Introduction

Many beginners in CNC milling projects face the dual challenges of cost overruns and insufficient precision, often leading to project delays or substandard quality. The core issue frequently lies in traditional approaches that overlook design-for-manufacturability optimization, leading to resource waste, compounded by a lack of professional guidance, which makes cost control difficult.

This article will introduce practical strategies for high-precision CNC milling, encompassing cost analysis, the use of online tools, and industry best practices. The following sections will provide a step-by-step guide to achieving efficient manufacturing.

What Are the Key Factors Affecting CNC Milling Costs for Manufacturing Projects?

Understanding the primary drivers of expense is the first step toward effective budget management in any manufacturing project. The final CNC Milling Cost is a function of several interconnected variables.

Fundamental Drivers of CNC Milling Costs

The total expense of a project is primarily governed by two key factors: the intrinsic properties of the part itself and the scale of production. Understanding these drivers is essential for accurate budgeting in Precision Machining.

l Intrinsic Factors: Material and Design

The selection of material is a primary cost driver in metal CNC milling, as raw material costs and, more critically, machinability vary greatly. For example, aluminum is easy to cut, enabling faster cycles and lower costs, whereas stainless steel requires more robust tools and slower speeds, increasing the price. Simultaneously, design complexity directly dictates machining time. Features like deep pockets, sharp internal corners, and thin walls necessitate specialized tooling and slower operations, elevating the final CNC Milling Cost.

l Extrinsic Factor: Production Volume

The batch size significantly impacts economies of scale. As outlined in guides like the NIST Manufacturing Cost Guide, low-volume or prototype orders bear higher fixed setup costs for programming and fixturing. When production quantities increase, these initial costs are distributed across more units, substantially reducing the price per part. Acknowledging this relationship is vital for effective project planning and cost control.

Post-Processing and Finishing Requirements

The journey of a part often extends beyond basic milling. Additional requirements such as tight tolerances, specific surface finishes, or secondary processes like heat treatment add layers of cost. A prime example is surface finishing; for instance, achieving a Mirror Polishing for Stainless Steel Parts requires meticulous, multi-stage polishing, which demands significant skill and time. Clearly defining necessary versus nice-to-have specifications during the design phase is key to controlling expenses in Precision Machining.

How Can Beginners Achieve High-Precision Results with CNC Milling?

Achieving High-Precision CNC Milling is essential for creating functional and reliable Precision Parts. This outcome relies on a systematic approach to the entire manufacturing process, not just the capability of the machine.Precision begins with machine integrity and calibration. The geometric accuracy of the CNC machine, thermal stability of its spindle, and the runout of the tool-holding system form the foundation for accuracy. Regular maintenance and calibration against standards such as those from ASME ensure the equipment performs to its specifications. For CNC Prototyping, selecting a partner with a rigorous machine maintenance protocol is a critical first step.

The principle of tolerancing is another cornerstone. Applying unnecessarily tight tolerances (e.g., ±0.005mm) to non-critical features can exponentially increase machining difficulty, inspection time, and cost. Beginners should adhere to the “as loose as possible” rule, referencing standards like ASME Y14.5 to apply strict tolerances only where functionally necessary.

A robust quality control system creates a closed-loop process that guarantees outcomes. This includes First Article Inspection (FAI), in-process checks, and final verification with a Complete Dimensional Report. Working with manufacturers certified to ISO 9001 and AS9100D provides assurance that their entire workflow is governed by international standards, offering traceability and reliability for CNC Prototyping projects.

What Materials Are Best for Cost-Effective CNC Milling in Prototyping?

Selecting the right material for a prototype is a balance between performance, cost, and manufacturability. An optimal choice directly influences the budget and success of producing CNC Milling Parts.

Alternative Materials for Specific Prototype Needs

Material selection for prototypes is dictated by functional requirements beyond basic machinability. When standard materials like aluminum are unsuitable, two distinct categories offer specialized solutions.

l Stainless Steel for Demanding Applications

For prototypes requiring superior strength, hardness, or corrosion resistance, stainless steel grades like 304 or 316 are the primary alternatives. However, this comes with notable trade-offs in metal CNC milling. Stainless steel is significantly more challenging to machine, demanding tougher tooling, slower cutting speeds, and more rigid setups. These factors inherently lead to longer cycle times and higher per-part costs. Consequently, it should be selected strictly when its specific mechanical or chemical properties are indispensable for the prototype’s function.

l Engineering Plastics for Lightweight and Functional Needs

For applications prioritizing light weight, electrical insulation, or chemical resistance, engineering plastics such as POM (Delrin), Nylon, or PEEK present excellent alternatives. These materials are generally easier and faster to machine than metals, which can further reduce CNC Milling Cost and lead times. This makes them ideal for the rapid validation of a design’s form, fit, and basic function in non-structural or low-load scenarios during the CNC Prototyping phase.

Aligning Material with Prototype Purpose

The ultimate decision should be driven by the prototype’s intended use. Is it for visual assessment, fit-check assembly, or functional testing under load? Defining this goal enables a cost-effective choice, often with guidance from experienced manufacturers. To explore material options and capabilities further, reviewing a professional high-precision CNC milling services platform is recommended.

How to Use Online Tools for Efficient CNC Milling Parts Ordering?

Digital platforms have revolutionized the initiation of CNC Prototyping projects. Online tools empower beginners to launch manufacturing requests with the efficiency of an expert.Modern Custom stainless steel parts manufacturer portals feature instant quoting and Design for Manufacturability (DFM) analysis systems. By simply uploading a 3D model file, the system automatically analyzes geometry, material volume, and machining complexity to generate a transparent cost and lead-time estimate within minutes.

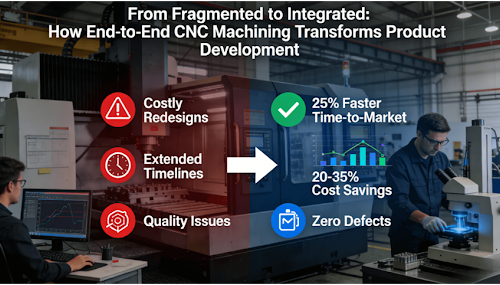

The key benefit is immediate feedback. The system or a support engineer will flag potential design issues such as hard-to-reach areas, excessively thin walls, or features requiring special fixtures. This serves as a free expert review before production begins, preventing costly redesigns and delays later. This trend towards digital collaboration, supported by organizations like NIST, is a significant driver for reducing waste in modern manufacturing.

Why Is Precision Machining Crucial for Avoiding Common Project Pitfalls?

Precision Machining is not merely about achieving accurate dimensions; it is a proactive strategy to avoid common project pitfalls and control long-term costs.Many project overruns stem from hidden costs: assembly failures, functional deficiencies, and the subsequent need for rework or complete remanufacturing due to poor part quality. High-Precision CNC Milling prevents this waste by ensuring parts are correct the first time. A precisely machined component fits perfectly with its counterparts, eliminating manual fitting and saving significant time and labor.

Case studies demonstrate that while the initial CNC Milling Cost for a high-precision part might be marginally higher, the long-term savings are substantial. By minimizing errors and rework, projects can be completed faster and with greater predictability. For example, a manufacturer known for its rigorous standards, such as JS Precision, demonstrates how embedding precision control into every production step helps clients avoid costly delays, leading to overall cost savings that can reach 30% or more.

Conclusion

This article has outlined the key factors influencing CNC milling costs and provided a framework for achieving high-precision results. By applying strategies for design optimization, material selection, and leveraging digital tools, beginners can significantly improve project efficiency and quality.

The next step is to put this knowledge into practice. For any upcoming CNC milling project, utilizing these guidelines is essential. Begin by visiting a professional online manufacturing platform to upload your design files for instant DFM feedback and a quote. This is the most effective way to start your project, ensuring cost savings while meeting industry standards.

Author Biography

The author is a manufacturing specialist with over a decade of experience in the CNC machining and precision manufacturing sector. He focuses on translating complex engineering concepts into practical guidelines to help designers, engineers, and enthusiasts enhance their skills and bring innovative ideas to life efficiently and economically.

FAQs

Q1: What is the average cost savings for projects using these CNC milling tips?

A: Projects can typically save up to 30% on costs by optimizing designs and material selection, based on industry data from sources like NIST.

Q2: How can I verify the precision of CNC milled parts for prototypes?

A: Utilize online tools and consult with manufacturers holding certifications like ISO 9001 to ensure tolerances meet standards. Requesting a First Article Inspection report is also a reliable method.

Q3: What materials are most affordable for beginner CNC milling projects?

A: Aluminum and plastics like POM are cost-effective options; always balance cost with the project’s durability and functional requirements.

Q4: Are online CNC milling services reliable for small batches?

A: Yes, many platforms provide instant quotes and DFM analysis, making them an ideal choice for prototypes and small-batch orders.

Q5: How does high-precision milling reduce long-term costs?

A: It minimizes errors and rework, leading to faster project completion and lower overall expenditure by preventing delays and ensuring part quality from the start.