Introduction

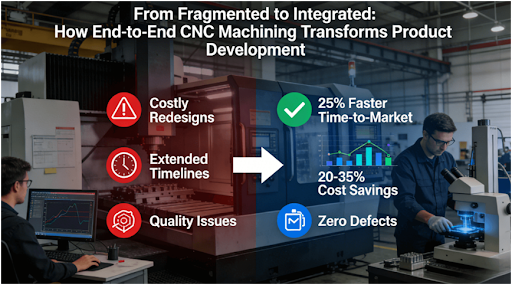

Startups, engineers, and students often face significant hurdleswhen transforming innovative designs into functional products, including unmanufacturable designs, slow prototype iterations, and uncontrolled costsfor small-batch production. This disconnect between design and manufacturing severely impedes innovation and time-to-market. The core issue lies in the traditional fragmented approach, where design, prototyping, and production are handled by separate teams or suppliers, leading to information silos, communication gaps, and unclear accountability.

This article explores an integrated solution—end-to-end CNC machining services—which seamlessly connects design analysis, rapid prototyping, and volume production to mitigate these risks. By adopting this model, teams can avoid common pitfalls and accelerate development. The following sections break down how this approach transforms product development.

What Challenges Arise from Disconnected Design and Manufacturing Processes?

A fragmented workflow creates multiple pain points that derail projects. Understanding these challenges is the first step toward adopting a more integrated strategy.

1. Design Flaws Due to Lack of Manufacturability Expertise

Design errorsoften arise when creators overlook manufacturing constraints, resulting in features that are impossible or prohibitively expensive to produce. For example, thin walls or sharp internal cornersmay lead to tool breakage or excessive machining time. According to the ASME Y14.5 standard, clear geometric dimensioning and tolerancing are critical for accurately conveying design intent. Without early design for manufacturability (DFM) analysis, teams risk costly redesigns late in the process, inflating budgets by up to 30%.

2. Communication Inefficiencies and Extended Timelines

Disjointed communicationbetween design and production teams causes misinterpretations, requiring repeated clarifications that delay progress. In one case, ambiguous drawingsled to three revision cycles, adding two weeks to the schedule. This inefficiency is compounded when different suppliers use incompatible software or terminology. A centralized communication channel, as seen in integrated approaches, reduces these delays by ensuring all stakeholders work from a single source of truth.

3. Inconsistent Quality from Misaligned Expectations

When manufacturers fail to fully grasp design intentions, quality inconsistenciesemerge, such as dimensional inaccuracies or surface defects. A study showed that poorly communicated specscaused a 15% scrap rate in aerospace components. By contrast, integrated workflows maintain consistent standardsthrough shared documentation and real-time feedback loops, ensuring final parts meet exact requirements.

How Does an End-to-End Approach Transform the Product Development Cycle?

End-to-end services consolidate the entire process under one roof, eliminating friction points and enhancing efficiency. This transformation hinges on unified responsibilityand streamlined workflows.

1. Single-Source Accountability and Seamless Transitions

Single-point accountabilityensures that one team manages the project from concept to completion, reducing finger-pointing and gaps. For instance, a medical device developer cut time-to-market by 25% by avoiding handoffs between vendors. This integrated managementallows for smoother transitions between phases, as design changes are immediately reflected in production planning. For teams seeking to optimize workflows, understanding the value of end-to-end CNC machining servicesis crucial.

2. Accelerated Iterations with Real-Time Data Sharing

Integrated information systemsenable instant updates across design and manufacturing, slashing iteration cycles. A robotics startup reduced prototype lead times from three weeks to one by using cloud-based CAD/CAM integration. This agility allows for rapid validation of design modifications, ensuring that product refinementoccurs continuously without costly pauses.

3. Cost Savings through Process Optimization

By eliminating redundant steps and reducing administrative overhead, end-to-end models can lower total costs by 20-35%. One consumer electronics project saved $50,000 through consolidated toolingand bulk material purchasing. These efficiencies make end-to-end CNC machining solutionsparticularly advantageous for budget-sensitive innovations.

Why is Early Design for Manufacturability (DFM) Analysis Critical for Success?

DFM analysis identifies production issues before machining begins, preventing expensive revisions. Its early application is vital for economic and technical viability.

l Proactive Optimization of Part Geometry: Early DFM feedbackhighlights problematic features like inadequate wall thickness or hard-to-machine angles, allowing designers to adjust models before prototyping. In automotive parts, this step reduced material waste by 40% by suggesting alternative geometries. This proactive tweaking ensures that custom CNC machining partsare both functional and economical.

l Material and Tolerance Recommendations: DFM experts advise on suitable materialsand realistic tolerances, balancing performance with cost. For example, switching from titanium to aluminum for a non-structural component maintained strength while cutting expenses by 50%. In regulated sectors like medical devices, adherence to ISO 9001 standardsthrough DFM ensures compliance from the outset.

l Risk Mitigation and Timeline Assurance: Addressing manufacturability early avoids late-stage surprises, such as unexpected tooling costs or assembly issues. A case study on drone frames showed that DFM cut debugging time by half, accelerating launch. This preventive approachis foundational to efficient product development.

What Role Does Precision Prototyping Play in Mitigating Production Risks?

Prototypes validate designs in real-world conditions, uncovering flaws before full-scale production. High-fidelity prototypesare indispensable for risk reduction.

1. Functional Testing and Design Verification

Functional prototypesallow engineers to test fit, form, and performance under operational stresses. A gear mechanism prototype revealed misalignments that, if uncaught, would have caused 20% failure rates. Precision CNC machining servicesproduce parts that mirror final products, enabling accurate validation.

2. User Feedback and Iterative Refinement

Early user testingwith tangible prototypes gathers insights that inform design tweaks, enhancing usability. A startup iterated three times in two weeks using rapid CNC prototyping, refining ergonomics based on feedback. This iterative cycleensures market readiness.

3. Cost-Effective Validation for Complex Assemblies

Prototyping complex assemblieschecks interfaces between components, preventing mismatches during mass production. An industrial sensor project used multi-part prototypesto avoid $100,000 in retooling, showcasing howCNC prototyping and productionde-risks scaling.

How is Consistent Quality Ensured in Low-Volume and Mass Production?

Quality consistency is maintained through rigorous systems that monitor every production stage. Standardized processesare key to reliability at scale.

- First-Article Inspection and Statistical Control: First-article inspection (FAI)validates initial parts against specs, while statistical process control (SPC)tracks variations during runs. A supplier using SCP held diameters within ±0.01mm across 10,000 units, achieving near-zero defects. Suppliers with certifications like AS9100D (aerospace) and IATF 16949 (automotive) embed these checks into their quality management systems.

- Advanced Metrology and Real-Time Monitoring: CMMs and optical scannersperform full-dimensional checks, with data logged for traceability. Real-time sensors detect tool wear, triggering auto-compensation. This closed-loop quality controlis vital for high-stakes industrieswhere failures are unacceptable.

- Scalability without Compromise: Modular production linesadapt to volume changes while maintaining standards. For low-volume manufacturing solutions, this flexibility ensures cost-effectiveness without sacrificing precision. A partner experienced in custom CNC machining servicescan deliver this consistency.

Conclusion

Adopting end-to-end CNC machining servicestransforms product development by integrating design, prototyping, and production. This model eliminates costly inefficiencies, ensures quality consistency, and accelerates time-to-market. By prioritizing early DFM, precision prototyping, and robust quality systems, teams can avoid the pitfalls of fragmented approaches and achieve smoother, more predictable outcomes.

FAQs

Q1: What is the main difference between traditional CNC machining and an end-to-end service?

A: Traditional CNC machining focuses solely on production after design finalization, whereas end-to-end servicesmanage the entire process from design consultation and DFM analysis through prototyping and production. This integration ensures manufacturability from the start, reduces communication gaps, and provides single-source accountability, leading to faster time-to-market and higher quality.

Q2: How does end-to-end CNC machining benefit small-batch or prototype projects?

A: It is ideal for small-batch projectsby involving manufacturing expertise early to prevent unmanufacturable designs. Rapid prototyping allows quick iterations, minimizing risks before production. This streamlined process makes low-volume productioncost-effective for startups and R&D teams.

Q3: What industries commonly utilize these integrated manufacturing solutions?

A: Industries with high precision demands, such as aerospace, medical devices, automotive, and robotics, heavily rely on these services. They benefit from the ability to produce complex geometrieswith consistent quality and compliance to stringent standards.

Q4: Can end-to-end services handle projects with very tight tolerances and specific material requirements?

A: Yes, reputable providers specialize in high-precision manufacturing, handling tolerances as tight as ±0.005mm and materials from aluminum to PEEK. Their advanced equipmentand quality systemsensure adherence to strict specifications.

Q5: What file formats are typically required to get started with a quote for CNC machining?

A: Preferred formats include STEP, IGES, or native CAD files(e.g., .sldprt), accompanied by a 2D PDF drawingfor critical dimensions and tolerances. This ensures accurate quoting and DFM feedback.

Author Bio

The author is part of the team at LS Manufacturing, a provider of integrated manufacturing solutions specializing in high-precision CNC machining, sheet metal fabrication, and 3D printing. With expertise in serving sectors like aerospace and medical devices, the company helps innovators navigate complex production challenges. To explore how an end-to-end approach can benefit your next project, request a instant quoteor visit their website for a free DFM consultation.